Energy Markets Products

Energy Markets

-

Odorant Delivery Specialists

Our Odorant Delivery Specialists are the backbone of our exceptional customer satisfaction. They are full-time, odorant-only experts in handling the movement of odorants. With their dedication and meticulous knowledge of our specialized closed-loop, odor-free delivery process, they ensure that each delivery is executed to the highest standards.

-

Owned and Operated Fleet of Tank Trucks

With our fleet of owned and operated tank trucks and US & Canada storage terminal network, M Chemical is an end-to-end expert in timely, safe, and odor-free deliveries across North America.

-

Consistent Supply and Timely Deliveries

M Chemical proactively works with customers to understand their supply needs so that our customers receive their odorant deliveries before they need it, ensuring they avoid emergency shortages and never run out.

-

No Customer Too Big or Too Small

- – Bulk Tank Truck Delivery

- – 5, 50, 100 & 600 Gallon Returnable Pressurized Cylinders

- – 1, 5, & 55 Gallon Non-Returnable Drums

- – Farm Tap / Bypass / Wick Odorization

- – Bulk Tank & Containment Supply

- – Bulk Tank & Containment Rental

-

KOH Briquettes

M Chemical manufactures high quality Potassium Hydroxide (KOH) Briquettes to aide in the removal of moisture and other impurities.

-

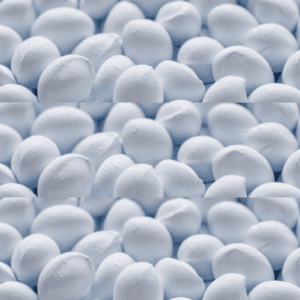

OXYMAX™ Molecular Sieves

M Chemical’s OXYMAX™ line of molecular sieves was developed specifically for medical oxygen applications.

-

High Void Inert Topping, Rings, Trilobes, and Bed Grading Solutions

At M Chemical Company, our advanced bed grading solutions deliver unparalleled efficiency and reliability. Our expertise in production, design and technical support of High Void Bed Grading solutions ensures optimal pressure drop relief and protection from foulants entering the reactor and maximizing the reactor run life.

Foulants enter the reactor in many forms and from many sources:

- – Iron scales and sulfides

- – Coke fines

- – Catalyst fines

- – Polymerized foulants

- – Sediment

- – Salts, etc.

Our shape optimized materials have optimum trapping volume for particulate contaminants from any feedstock while still providing superior flow distribution through the reactor.

Our Top Bed Loading designs are tailored to the specific contaminants and foulants entering the reactor as well as the reactor dimensions in order to maximize catalyst run life and eliminate the need for reactor skims prior to scheduled turnarounds.

In addition to our wide range of high void inert shapes, we offer a complete family of Active grading solutions for trapping or removing Arsine, Silica, Nickel, Vanadium, Mercury, Lead and other metal sulfides. We offer grading rings and trilobes in every size. Each product is tailored with the optimum activity, surface area, pore volume and shape to protect the main bed catalyst and optimize run life.

We also offer extensive post-mortem testing and evaluation of products used in the Top Bed Grading section. We can determine what foulants entered the reactor, we can evaluate the effectiveness of each product based on what it was able to trap and where it was loaded. As feedstocks change, loading schemes may need to change as well and understanding what is working and what did not work, from post mortem testing, allows the refiner and M Chemical to work together to optimize future loadings.

Whether your goal is to extend the run life of a Pressure Drop Limited reactor, or to have a wider selection of choices of products to load, or to simply reduce the cost spent on the Top Bed Grading section, M Chemical has the solution. Partner with us for your bed grading needs and experience exceptional pressure drop relief, enhanced reactor performance, and increased profitability. We will deliver the quality and reliability your operations demand. Contact us today to get started.

-

PURAMAX® Purification Technologies

M Chemical’s PURAMAX® line of purification technologies are engineered to deliver consistent, high-performance results across a wide range of industrial applications. This includes the removal of sulfur, chloride, arsenic, fluoride, mercury, oxygen, silica, and more.

PURAMAX® Sulfur Species Removal

Our sulfur purification technologies effectively eliminate sulfur compounds from process streams. This reduces corrosion and catalyst poisoning while improving product quality across refining, petrochemical, and natural gas processing applications.

PURAMAX® Chloride Removal

This technology targets and removes chloride contaminants that can corrode equipment and degrade catalysts. This helps protect process integrity in refining, petrochemical, and syngas applications.

PURAMAX® Arsenic Removal

Our arsenic purification technologies remove arsenic from feedstocks to protect downstream catalysts, ensure regulatory compliance, and maintain safe, efficient operation in refining, petrochemical, and natural gas processing applications.

PURAMAX® Fluoride Removal

This technology removes harmful fluoride ions from gas and liquid streams, helping to preserve equipment lifespan and safeguard catalyst performance. It is especially valuable in refining applications such as HF alkylation units, where fluoride contamination poses significant corrosion risks.

PURAMAX® Mercury Removal

Our mercury purification technologies capture toxic mercury from natural gas and petrochemical streams, preventing environmental release and equipment contamination. They are particularly critical in cryogenic natural gas processing units and chlor-alkali or VCM production, where mercury poses severe risks to equipment integrity and catalyst performance.

PURAMAX® Oxygen Removal

This technology reduces oxygen levels in gas and liquid systems to prevent unwanted oxidation reactions and maintain process stability in hydrogenation, polymerization, and chemical synthesis operations.

PURAMAX® Silica Removal

Our silica purification technologies remove silica to protect catalysts, membranes, and other sensitive equipment. It also ensures operational efficiency and reduces fouling in gas treatment, steam generation, and petrochemical facilities.

-

PURAMAX® BTX Clay

M Chemical’s PURAMAX® BTX clay products offer superior quality, consistency and availability.

Each batch of PURAMAX® BTX Clay undergoes rigorous quality assurance and control to ensure consistent performance, purity, and reliability across a wide range of Aromatics production processes. Engineered for uniformity and consistent bulk density, it supports efficient loading and predictable performance in diverse system configurations. PURAMAX® BTX Clay delivers long service life in demanding applications, including the removal of olefins from aromatic streams, basic nitrogen compounds from benzene feeds, and color improvement in other organic feedstocks. It is also widely used in linear alkylbenzene (LAB) production and BTX purification processes to meet stringent product specifications and enhance final product quality.

M Chemical’s dedicated technical team provides expert guidance, troubleshooting, and process optimization to help clients maximize product performance and extend operational efficiency. Strategically located inventories worldwide allow for quick delivery, reducing downtime and maintaining supply chain continuity across global refining, petrochemical, and specialty chemical markets.

Our purification technologies deliver exceptional results, and we have local stock available worldwide. Contact our team today to request a quote!

-

Random Tower Packing

At M Chemical, we understand the critical role that random tower packing plays in optimizing your industrial processes. By improving mass transfer and fluid distribution, our high-quality random tower packing solutions help increase efficiency and reliability across a variety of applications. Whether you’re working in distillation, absorption, or extraction, the right tower packing can significantly impact your process performance and overall costs. That’s why we offer a comprehensive selection of random tower packing options, each designed to meet the specific requirements of your operation.

- Examples Include:

- – Metal Random Packing

- – Metal N-Rings, Metal Pall Rings, Metal Raschig Rings, Metal Saddle Rings

- – Ceramic Random Packing

- – Ceramic Pall Rings, Ceramic Raschig Rings, Ceramic Berl Saddles, Ceramic Saddles

- – Carbon/Graphite (UOP Approved)

- – Carbon Raschig Rings

- – Plastic Random Packing

- – Plastic Pall Rings, Plastic Saddles, Plastic Super Saddles

- – Tellerette Packing

- – Tri-Pack Scrubber Packing

More information on our products can be found in our random tower packing brochure below. Additional sizes and materials can be made available upon request.

Metal and Ceramic Random Packing

Our metal random packing options are durable and corrosion-resistant, making them ideal for high-temperature and aggressive chemical environments. These packings are particularly effective in processes where high strength and heat resistance are required, such as in refineries and petrochemical plants. We also provide ceramic random packing, known for its excellent thermal stability and ability to handle extreme conditions, making it a popular choice for acid and high-temperature applications.Carbon/Graphite and Plastic Random Packing

For specialized applications, M Chemical offers carbon/graphite random packing that is UOP approved, providing outstanding chemical resistance and performance in harsh environments. Additionally, our plastic random packing is lightweight and resistant to corrosion, making it suitable for a wide range of applications where less aggressive conditions are present.Why Work With M Chemical?

At M Chemical, we recognize that every process is unique, which is why we offer a variety of materials and sizes to fit your specific needs. Our team of experts is available to assist with selecting the right random tower packing solution for your operation, ensuring you achieve maximum efficiency and performance. If you have specific requirements or need a custom solution, additional sizes and materials can be made available upon request.